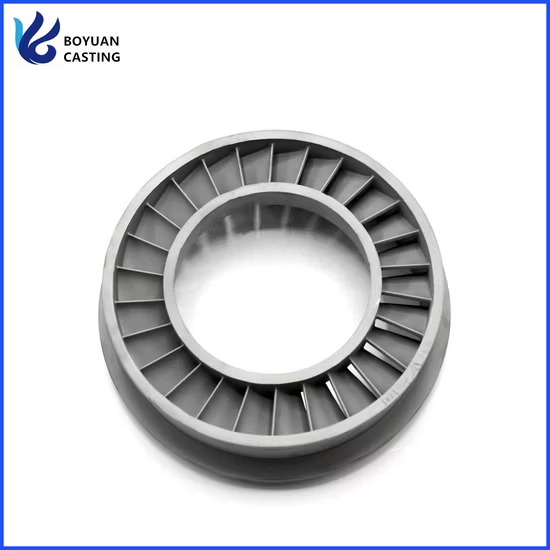

Super Alloy Lost Wax Investment Vacuum Casting Turbine Blade Wheel Nozzle Ring Guide Vane

Basic Info.

| Model NO. | P22.1 |

| Surface Roughness | Ra3.2 |

| Machining Tolerance | +/-0.02mm |

| Standard | ASTM |

| Certification | ISO9001:2015 |

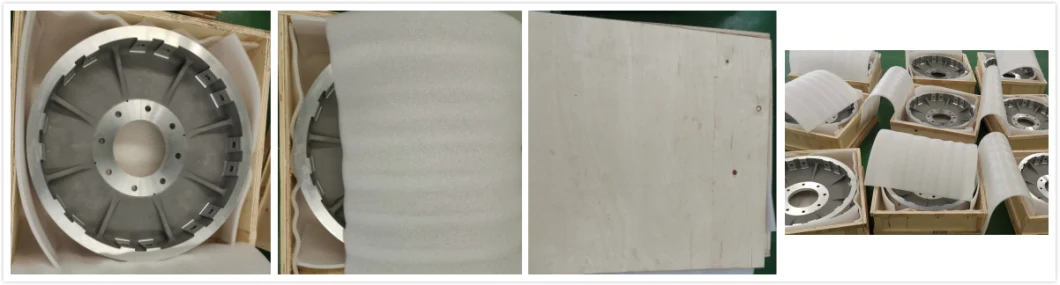

| Package | Carton Box, Plywood Cases |

| Service | OEM and Customized |

| Size | as Per Customer′s Requirements |

| Usage | Turbojet Engine |

| Sample | 1 or 2 Pieces |

| Technics | Lost Wax Casting |

| Machining Service | Yes |

| Surface Treatment | Sand Blasting and Polishing |

| Raw Material | Inconel 713c |

| Item | Nozzle Guide Vane |

| Transport Package | Plywood Case |

| Specification | diamteter: 640mm |

| Trademark | BOYUAN |

| Origin | Weifang |

| HS Code | 8414909090 |

| Production Capacity | 100000pieces/Years |

Product Description

Super Alloy Lost Wax Investment Vacuum Casting Turbine Blade Wheel Nozzle Ring Guide Vane

Superalloy nozzle ring used for Locomotive and Marine turbocharger, turbo nozzle ring be finished by integral casting. And casting method of noizzle ring is lost wax investment & vacuum casting, casting surface smoothness can meet Ra3.2μm, production process of nozzle ring is Silica sol process. The blade thickness is 0.5mm.The material of nozzle ring is superalloy IN718. Please see the material chemical composition:

| Element | C | Cr | Co | Mo | Ni | Fe | Mn | Si | S | Cu |

| Content | ≤0.08 | 17.0-21.0 | ≤1.0 | 2.8-3.3 | 50-55 | BAL | ≤0.35 | ≤0.35 | ≤0.015 | ≤0.30 |

| Element | Al | Ti | ||||||||

| Content | 0.2-0.8 | 0.65-1.15 |

Detailed Photo

| Item | Annual output | Max weight&size | material | Remark | |

| Lost wax vacuum casting | 200TON | 60KG | φ700 | NI BASE ALLOY, HIGH HEAT RESISTING, HIGH CORROSION, RESISTING ALLOY | IN718,IN713C,IN713LC,IN738,IN738LC,IN792,IN625,MAR247,K465,K424,K417G... |

About casting production equipment we have: * Aluminum low pressure casting furnace * Vacuum casting furnace * Injection wax machine * Shell drying line * Constant temperature and humidity room * Plaster shell chamber * Sandblasting machine * Heat treatment furnaceAbout machining production equipment we have: * DMG five axis machining center * Three axis machining center * Doosan CNC center Lathe * General CNC Lathe * Dynamic balancing machine * Overspeed testing machine * Radial Drilling machine

Our Company Profile:

Weifang Boyuan Power Technology Co., Ltd. is founded in 2018, it is located in the beautiful world kite capital - Weifang Anqiu, just 140 kilometers far away from Qingdao port. We produce various kinds of low-pressure casting aluminum alloy parts, the main products include: Blower fan impeller, blower fan, fan blade, centrifugal fan impeller, axial fan impeller, closed impeller, open impeller, single blade, wheel hub, housing, casing and so on. At the same time, our company imported DMG five-axis machining center from German, in order to process the impeller of aluminum alloy and titanium alloy. Our products are widely used in superchargers, aero engines, industrial fans, rail transit, heavy mining machinery industry, refrigeration industry, marine engineering industry and so on.Weifang Boyuan Power Technology Co., Ltd. Specializes in the production of Aluminum Alloy impeller products and High temperature alloy impeller products, stainless steel impeller products. The company has a professional team that has long been engaged in the casting, processing and testing of impellers. Products are widely used in turbochargers, aero engines, industrial fans, compressors, blowers, rail transit, heavy mining machinery industry, refrigeration industry, marine engineering industry. The company has professional production line of Aluminum Alloy low pressure casting and high temperature alloy casting, stainless steel casting equipped with advanced inspection instrument.

Our Advantages:

1. We can finish mould design and mould machining, mould assembly in our factory to ensure plan of casting2. We can finish all casting and machining in our factory to ensure production time3. We can finish all inspection in our factory to ensure production quality

Packaging